In the bustling industrial landscape of India, where precision and quality are the lifelines of manufacturing, ensuring consistent accuracy is a perennial challenge. Meet Rajesh Verma, a diligent quality control manager at a mid-sized automotive components manufacturing unit in Pune. Rajesh, like many in his field, faces the daunting task of maintaining stringent quality standards amidst increasing production demands. His story represents a widespread challenge in the industry, where the balance between speed and precision can often be elusive.

For Rajesh, mornings start with a routine inspection of the previous night’s production. The company he works for, Bharat Auto Components, prides itself on delivering top-notch products to prestigious clients. However, like many manufacturers, they face a significant problem ensuring that each component meets the precise measurements required by their clients. A single defect can lead to costly recalls, damage to reputation, and strained client relationships.

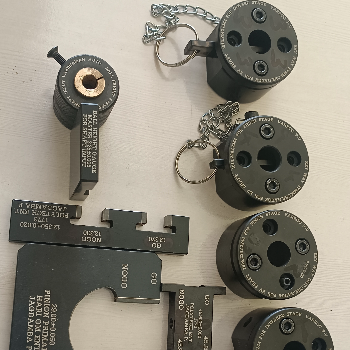

The root of Rajesh’s problem lies in the tools he uses for quality control. Traditional gauges, often prone to wear and tear, can lead to inaccuracies over time. This is where SPL STD Gauges enter the scene, offering a transformative solution to Rajesh’s quandary.

SPL STD Gauges, known for their durability and precision, provide a reliable alternative to conventional measuring tools. Made from high-grade materials and designed to withstand rigorous usage, these gauges promise consistent accuracy, ensuring that every component produced aligns perfectly with client specifications. For Rajesh, incorporating SPL STD Gauges into his quality control arsenal was a game-changer.

Imagine a typical day at Bharat Auto Components. Rajesh, armed with his new set of SPL STD Gauges, begins his inspections. The gauges’ ergonomic design and easy-to-read measurements allow him to swiftly and accurately assess each component. The confidence in knowing that the tools will not falter gives Rajesh peace of mind. No longer does he worry about potential inaccuracies leading to production delays or customer dissatisfaction.

Furthermore, the emotional burden on Rajesh is significantly reduced. The fear of unnoticed defects slipping through the cracks is alleviated, replaced by trust in the reliability of SPL STD Gauges. This emotional relief is invaluable, allowing Rajesh to focus more on optimizing processes and less on firefighting quality issues.

Consider the case of Arvind Industries in Chennai, another manufacturer who faced similar challenges. Before adopting SPL STD Gauges, they struggled with frequent discrepancies in their parts, resulting in a tarnished reputation and lost contracts. However, since making the switch, Arvind Industries has seen a marked improvement in their quality control processes. Customer complaints have decreased, and their reputation for precision engineering has been restored.

The impact of SPL STD Gauges extends beyond individual companies. On a larger scale, they contribute to the overall enhancement of India’s manufacturing standards. By providing a reliable solution to a common problem, these gauges help manufacturers across the country uphold the high-quality standards expected in today’s competitive market.

For Rajesh and many like him, SPL STD Gauges are not just tools, but partners in their quest for excellence. They symbolize a commitment to quality and precision, essential traits for any manufacturing enterprise aiming to succeed in a global marketplace.

In conclusion, the story of Rajesh and Bharat Auto Components highlights a critical issue faced by many in the manufacturing sector the struggle to maintain precision and quality under pressure. SPL STD Gauges offer a practical and emotional solution, ensuring accuracy and peace of mind. For quality control managers across India, these gauges are more than just instruments—they are a promise of reliability and a testament to the power of precision in Indian manufacturing.

Visit Vyaparify Site:

https://id.vyaparify.com/jagdamba-precision