In the bustling industrial heart of Pune, where machinery hums and innovation thrives, lives Rajesh, an experienced mechanical engineer. Rajesh has dedicated over two decades to the world of manufacturing, consistently striving for perfection in his work. But like many in the field, he faces a persistent challenge maintaining precision in measurement to ensure the quality and reliability of his products.

Rajesh's Challenge The Need for Precision

For Rajesh, the stakes are high. His company, which manufactures critical components for aerospace and automotive industries, relies heavily on precision gauges to ensure every part meets stringent quality standards. A minor deviation in measurement could lead to significant setbacks, costing time, money, and reputation.

Rajesh recalls a time when a slight miscalculation due to an inaccurate gauge led to an entire batch of components being rejected in a quality check. The stress of potentially losing a key client was overwhelming. It was in this moment of need that Rajesh found a solution in SPL STD Gauges.

SPL STD Gauges The Beacon of Precision

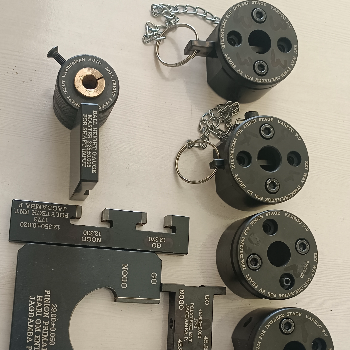

SPL STD Gauges stand out in the industry as a pinnacle of accuracy and reliability. Designed to cater to the demanding needs of industries like aerospace, automotive, and heavy machinery, these gauges offer an unrivaled level of precision that engineers like Rajesh can count on.

The gauges are crafted with meticulous attention to detail, enabling them to detect even the slightest deviations. This precision is not just a technical benefit; it transforms the entire manufacturing process. For Rajesh, using SPL STD Gauges means peace of mind, knowing that his measurements are exact and his products are flawless.

The Emotional Impact Confidence Restored

Beyond the practical benefits, SPL STD Gauges offer an emotional reprieve for professionals like Rajesh. The anxiety of potential errors is replaced with confidence. Rajesh can now approach his work with assurance, knowing that his measurements are accurate. This confidence trickles down to his team, creating a more productive and positive work environment.

Moreover, the reliability of SPL STD Gauges helps Rajesh in client communications. He can now guarantee the quality of his components, fostering trust and long-term relationships with his clients. This newfound assurance was beautifully illustrated when Rajesh successfully secured a contract with a major automotive company, thanks to the consistent quality his company could now deliver.

A Case in Point The Tale of Arjun Industries

Consider the experience of Arjun Industries, a mid-sized manufacturing firm in Chennai. Struggling with precision issues, the company faced multiple setbacks due to rejected batches. The introduction of SPL STD Gauges was a game-changer. Not only did it streamline their quality control process, but it also significantly reduced waste and increased efficiency.

The management reported a 30% improvement in production accuracy and a noticeable enhancement in client satisfaction. This transformation allowed them to expand their operations and enter new markets with confidence.

Embracing Transformation with SPL STD Gauges

In the world of manufacturing, precision is not just a requirement but a foundation for success. For professionals like Rajesh and companies like Arjun Industries, SPL STD Gauges are more than tools; they are partners in achieving excellence. By solving the critical challenge of precision, these gauges empower engineers and manufacturers to reach new heights, ensuring every component they produce is a testament to quality and reliability.

Investing in SPL STD Gauges is a step towards transforming challenges into opportunities, anxiety into assurance, and potential into achievement. For Rajesh and countless others, these gauges are the key to unlocking a future of precision engineering and unparalleled success.

Visit Vyaparify Site:

https://id.vyaparify.com/jagdamba-precision