In the bustling industrial landscape of India, precision is not just a requirement—it's a revolution. Meet Arjun, a seasoned production manager at a thriving automotive parts manufacturing company in Pune. Known for his meticulous attention to detail, Arjun constantly seeks tools that ensure perfection in every component his team produces. In the world of manufacturing, even a fraction of a millimeter can mean the difference between success and failure. This is where SPL STD Gauges come into play, transforming Arjun's challenges into triumphs.

The Challenge of Precision

Arjun's company, like many others, faces the relentless demand for precision. Every day, thousands of components pass through their assembly lines, destined for critical applications in vehicles. The stakes are high—any deviation can lead to faulty parts, dissatisfied customers, and costly recalls. For Arjun, ensuring that every component meets stringent quality standards is not just a job; it's a responsibility that weighs heavily on his shoulders.

The major problem Arjun faces is maintaining consistent accuracy amidst the fast-paced production environment. Traditional measurement tools often fall short, leading to discrepancies that can ripple through the entire manufacturing process. This is where the SPL STD Gauges emerge as a beacon of hope, offering a practical solution to Arjun's precision predicaments.

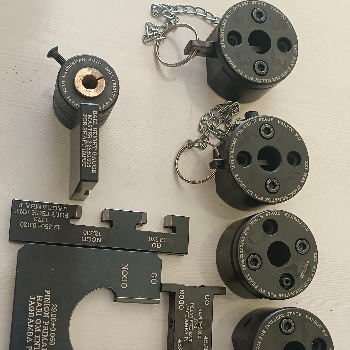

Enter SPL STD Gauges

SPL STD Gauges are designed to address the unique challenges of industries like Arjun's. Crafted with the highest standards of engineering, these gauges offer unparalleled accuracy and reliability. With SPL STD Gauges, Arjun can measure components with a level of precision that ensures each part fits perfectly, adhering to the strictest quality controls.

Imagine the relief on Arjun's face when he discovers that SPL STD Gauges can measure even the smallest deviations, providing the assurance he needs. These gauges are not just tools; they are Arjun's allies in his quest for excellence. The integration of these gauges into his workflow means fewer production errors, reduced waste, and most importantly, peace of mind.

A Real-Life Transformation

Consider the case of Meera Industries, another manufacturing giant based in Chennai, which faced similar challenges. They implemented SPL STD Gauges in their quality control processes and witnessed a remarkable transformation. Production errors dropped by 40%, and customer satisfaction soared. Meera Industries now stands as a testament to how precise measurement tools can revolutionize manufacturing.

The Emotional Journey

For Arjun, the impact of SPL STD Gauges transcends practical benefits. It's an emotional journey from uncertainty to confidence. Every time a component is measured with precision, it reinforces his belief in delivering excellence. The gauges bring a sense of empowerment, knowing that he can uphold the company's reputation for quality without the nagging fear of errors.

Persuasion and Precision

The story of Arjun and SPL STD Gauges is one of transformation. It's about acknowledging the challenges of precision in manufacturing and embracing a solution that not only solves practical problems but also alleviates emotional burdens. For companies across India, SPL STD Gauges represent a commitment to quality, efficiency, and progress.

In conclusion, SPL STD Gauges offer more than just precise measurements—they offer a path to excellence. For production managers like Arjun, they are the key to unlocking a future where every component is perfect, every customer is satisfied, and every challenge is met with confidence. Consider integrating SPL STD Gauges into your manufacturing processes and experience the transformative power of precision.

Visit Vyaparify Site:

https://id.vyaparify.com/jagdamba-precision