In the bustling heart of Pune's industrial hub, Ravi Kumar, a dedicated quality control manager, faced a recurring dilemma. Despite having a robust manufacturing process in place, his team often struggled with ensuring precision in the production of automotive components. This precision wasn't just an operational requirement; it was a promise of quality and reliability that Ravi’s company made to its clients. Every single flaw meant potential recalls, increased costs, and most importantly, a dent in the company's reputation.

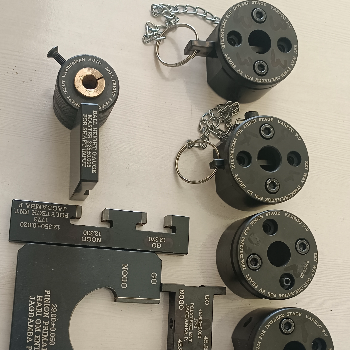

Ravi's story isn't unique. Across India, manufacturing industries face similar challenges. Precision in measurement is the backbone of industries ranging from automotive to aerospace. Even the slightest deviation from the specified dimensions can lead to catastrophic failures. Enter SPL STD Gauges – a game-changer in the world of precision measurement.

SPL STD Gauges are meticulously designed to address the crucial need for accuracy in manufacturing. For Ravi, they were not just tools but a practical solution to his pressing problem. Before integrating SPL STD Gauges into his workflow, Ravi often relied on traditional measurement tools. While these tools were serviceable, they often left room for human error and inconsistency. The SPL STD Gauges, with their advanced engineering, eliminated these discrepancies, providing consistent and reliable measurements every time.

The major problem faced by Ravi and many others in his field was maintaining stringent quality control standards without compromising on efficiency. The SPL STD Gauges became an essential asset in achieving this balance. They offered a level of precision that was previously hard to attain, ensuring that each component met exact specifications. This not only improved the quality of the final product but also significantly reduced wastage and rework, leading to substantial cost savings.

Moreover, the emotional relief that SPL STD Gauges brought to Ravi and his team was immeasurable. The anxiety of potential errors was replaced with confidence. The reassurance that every product leaving the facility was of the highest quality allowed Ravi to focus on other strategic aspects of his role, driving innovation and growth for his company.

Consider the case of Meena Joshi, an entrepreneur in Bengaluru running a mid-sized aerospace components manufacturing firm. She faced similar precision challenges and was on the brink of losing a major client due to quality inconsistencies. Adopting SPL STD Gauges transformed her production line. The reliable precision of these gauges restored her client's faith and opened doors to new opportunities, securing the future of her business.

For industries like automotive and aerospace, where precision is non-negotiable, SPL STD Gauges provide an unparalleled advantage. They are more than mere instruments; they are the cornerstone of quality assurance, ensuring that every bolt, nut, and component meets the exacting standards demanded by global markets.

In conclusion, SPL STD Gauges are not just solving a practical problem of measurement; they are elevating the standards of manufacturing across India. By ensuring precision and consistency, they help companies like Ravi's and Meena's not only survive but thrive in competitive landscapes. For any manufacturing unit grappling with precision issues, SPL STD Gauges offer a reliable, effective, and innovative solution.

Precision is more than a necessity in modern manufacturing; it's a testament to a company's commitment to excellence. With SPL STD Gauges, manufacturers can confidently pledge that commitment to their clients, ensuring quality, reliability, and trust in every product they deliver.

As Ravi Kumar often says, "In the world of precision, there are no shortcuts. SPL STD Gauges ensure that every measurement counts, every time."

Visit Vyaparify Site:

https://id.vyaparify.com/jagdamba-precision