In the bustling industrial hub of Chennai, Ravi, a diligent manufacturing engineer, faced a pressing challenge that was affecting his company's productivity. Ravi was known for his meticulous attention to detail and his commitment to delivering quality products. His company specialized in producing high-precision mechanical components, and while the demand for their products was soaring, maintaining accuracy and consistency was becoming an increasingly difficult task.

Each day, Ravi and his team would measure countless components, relying on traditional measuring tools. However, the process was time-consuming, and human errors were inevitable, leading to discrepancies in the final products. Ravi was determined to find a solution that would streamline their operations and ensure that every component met the stringent quality standards required by their clients.

One evening, while pondering over this predicament, Ravi came across a product that promised to revolutionize his approach to precision measurement—the Relation Gauge. Intrigued by its potential, Ravi delved deeper into understanding how this innovative tool could solve his problems.

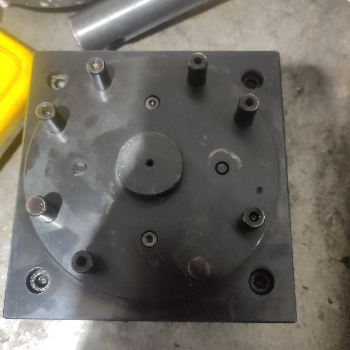

The Relation Gauge is not just a measuring tool; it is a testament to the evolution of precision engineering. Designed to eliminate the common pitfalls of traditional measurement methods, it offers unparalleled accuracy and consistency. Ravi realized that the Relation Gauge could be the answer to his quest for precision and efficiency.

The following week, Ravi introduced the Relation Gauge to his team. Initially skeptical, his team quickly embraced the tool as they witnessed its impact on their workflow. The Relation Gauge was easy to use, reducing the time spent on measurements and significantly minimizing errors. Its ability to provide consistent and precise measurements meant that Ravi's team could now focus on what they did best—manufacturing top-quality components without worrying about discrepancies.

As the weeks went by, the positive effects of this new tool became evident. The rejection rates plummeted, and customer satisfaction soared as clients received components that perfectly met their specifications. The Relation Gauge had not only improved their manufacturing process but had also enhanced the overall reputation of Ravi's company in the competitive market.

Ravi's story is a testament to how the right tools can transform an industry. The Relation Gauge addressed a critical challenge faced by many in the manufacturing sector—maintaining precision without compromising on productivity. It offered a practical solution to a problem that had both practical and emotional implications for Ravi and his team.

For manufacturing professionals like Ravi, the Relation Gauge is more than just a tool; it is a partner in the pursuit of excellence. It empowers them to uphold their promise of quality to their clients, building trust and fostering long-lasting relationships.

In conclusion, if you find yourself in a situation similar to Ravi's, grappling with the challenges of precision in manufacturing, the Relation Gauge might just be the solution you need. Its innovative design and exceptional accuracy can redefine your approach to precision measurement, enhancing your productivity and ensuring that your products consistently meet the highest quality standards.

By sharing Ravi's journey, we hope to inspire others in the manufacturing sector to embrace innovation and seek out tools that can drive efficiency and reliability in their processes. After all, in the world of manufacturing, precision is not just a requirement; it is the key to success.

Visit Vyaparify Site:

https://id.vyaparify.com/jagdamba-precision